"Our stainless steel water bottles maintain warm fluids hot and cold fluids cool" This is the very stating you can learn through water bottle providers and producers, given that the innovation of the insulated bottles. Yet exactly how? The answer is: foam or vacuum cleaner packaging abilities. Nonetheless, there is even more to stainless-steel water bottles than to satisfy the eye. One heavy-duty container is a container within a container. What's the deal? There is foam or a vacuum cleaner in between both containers. Containers filled with foam keep cold fluids chilly while vacuum-packed bottles maintain hot liquids warm. Considering that the early 1900s, this method has actually been using and revealed extremely effective, consequently becoming preferred amongst individuals who wish to drink on the move. Travelers, athletes, walkers, exterior task fans, and even busy people that take pleasure in warm water or cold water choose to have one and even some child bottles are additionally made insulated.

Background

Egyptians have made the very first well-known bottles, which remained in glass generated 1500 B.C. The method to make bottles was to put molten glass around the core of clay as well as sand up until the glass got cooled down and then dug out the core. It was fairly time consuming as well as therefore taken into consideration a deluxe things back then. The procedure has actually been simplified later in China and Persia with a method that molten glass was blown right into a mold. This was then adopted by Romans as well as spread all over Europe throughout the midlifes.

The automation assisted quicken container making in 1865 by using pressing and also blowing devices. Nonetheless, the very first automatic equipment for bottle production showed up in 1903 when Michael J. Owens put the equipment right into business usage for generating as well as producing bottles. This no doubt transformed the bottle making industry by transforming it into inexpensive and also large scale manufacturing, which also advertise the growth of the carbonated beverage sector. By 1920, Owens machines or various other versions produced most glass containers. It was until early the 1940s, plastic bottles were generated with blow-molding makers which heated tiny pellets of plastic material and after that vigorously put into a mold of an item. After that eliminate the mold after it cools. Made from polyethylene, the very first plastic bottles designed by Nat Wyeth, durable and sturdy enough to have carbonated beverages.

He secured one container inside another and also then pumped out the air inside which made his protected bottle. It was never ever patented until German glassblower Reinhold Hamburger and also Albert Aschenbrenner who previously functioned for Dewar founded a business to make the shielded container called Thermos, which was "threm" in Greek, indicating warm.

Currently it has actually been beautified and put huge range production with robotics. Purchasers can tailor the bottles they want, shades, size, logo designs and patterns even, direct from the manufacturing facility. People from Asia might choose hot water as this is conceived as a healthful routine while westerners delight in chilly drinks that makes the stainless-steel shielded water bottle a best option for both individuals.

Raw Materials

Plastic or stainless steel is used as the raw material in the manufacture of shielded bottles. They are additionally products for both internal and also outer cups. These in the assembly line process, are compatible and also well equipped. Foam is usually made use of in the production of shielded bottles for chilly beverages.

The Production Process

The foam

1. When delivered into the factory and these balls can then react to generate heat, the foam is usually in the form of chemical balls.

2. heat the fluid blend slowly to 75-80 ° F.

3. Wait till the mixture cools down gradually and then a fluid foam is basically down.

The bottle.

- 4. The outer mug has actually been created. It's been through a process called blow molding if it's made of plastic. As such, pellets of plastic resin would be heated and afterwards blown right into a mold and mildew of a certain form. It coincides instance for the stainless-steel cup.5. In the process of an assembly line, the internal and also outer liners are well-fitted. A glass or stainless steel filter, is placed inside and afterwards add the insulation, either foam or vacuum.

6. Matchmaking. A single system is created by silicone seal coating sprayed on the cups.

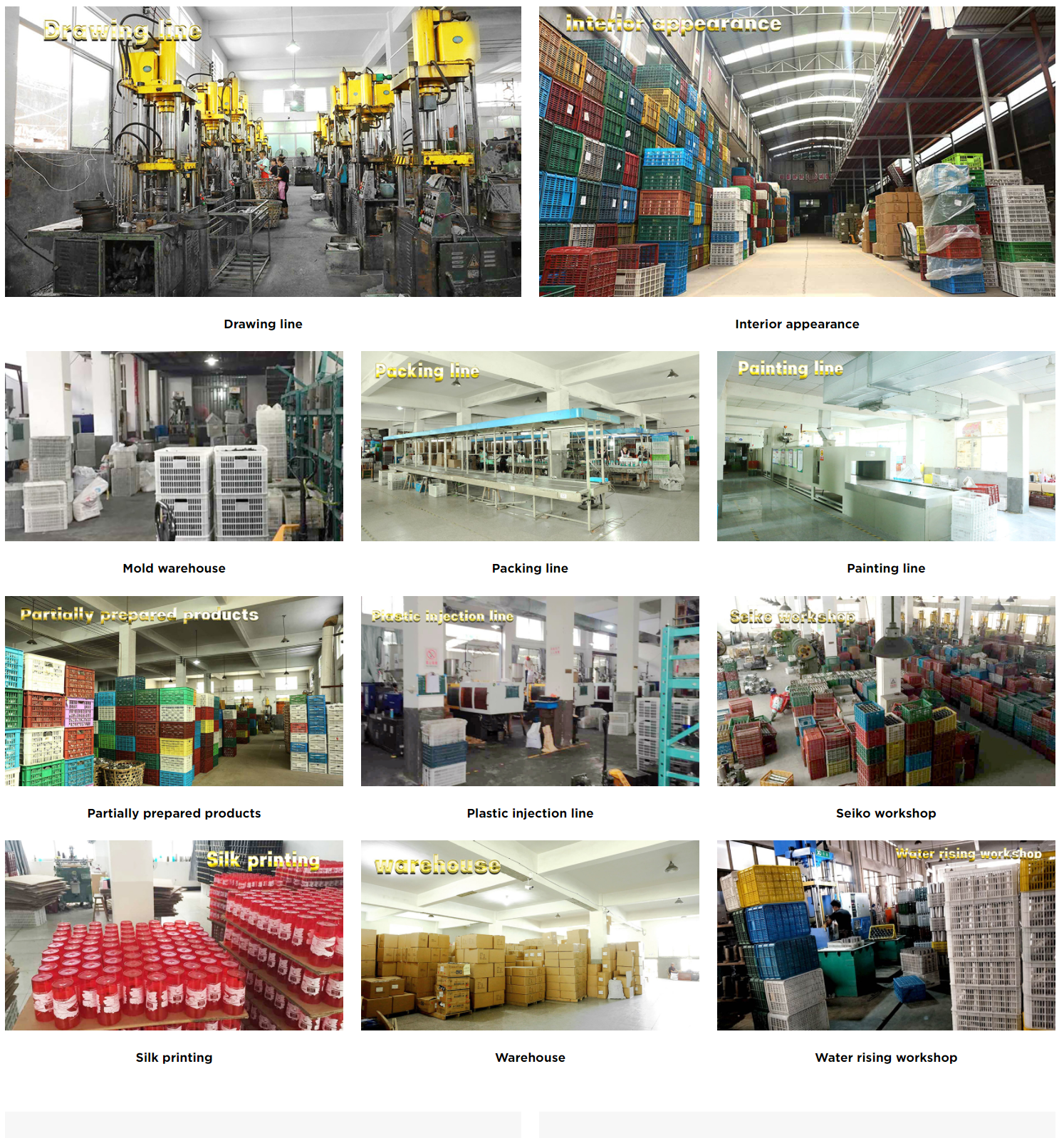

7. Improve the bottles. Stainless steel water bottles would be painted. In Jupeng Drinkware, we have the manufacturing facility for bottle manufacturing as well as automated spray finishing line which assures the quality as well as performance of huge scale manufacturing.

The Top.

The stainless steel water bottle tops are also made blow molded. The technique of tops is crucial for the quality of the entire bottles.

Jupeng Drinkware utilizes different innovative manufacturing abilities from automatic spray line to hands-on design of bottles. We are likewise partnered with Starbucks, with the assurance of FDA as well as FGB, looking forward to partnering with you. Call us here.

"Our stainless steel water bottles keep hot liquids hot and cold liquids cold" This is the very saying you can hear from water bottle suppliers and manufacturers, since the invention of the insulated bottles. One heavy-duty bottle is a bottle within a bottle. Containers filled with foam keep cold liquids cold while vacuum-packed bottles maintain hot liquids hot. The first automatic machine for bottle making appeared in 1903 when Michael J. Owens put the machine into commercial use for producing and manufacturing bottles. He sealed one bottle inside another and then pumped out the air inside which made his insulated bottle.

Consult for free access to the best selling product catalog

Post time: Apr-12-2022

![NB]QVCPH3YARYX5YN9C5UT3](/uploads/NBQVCPH3YARYX5YN9C5UT3.png)